Welcome to JL Glass Bottle!

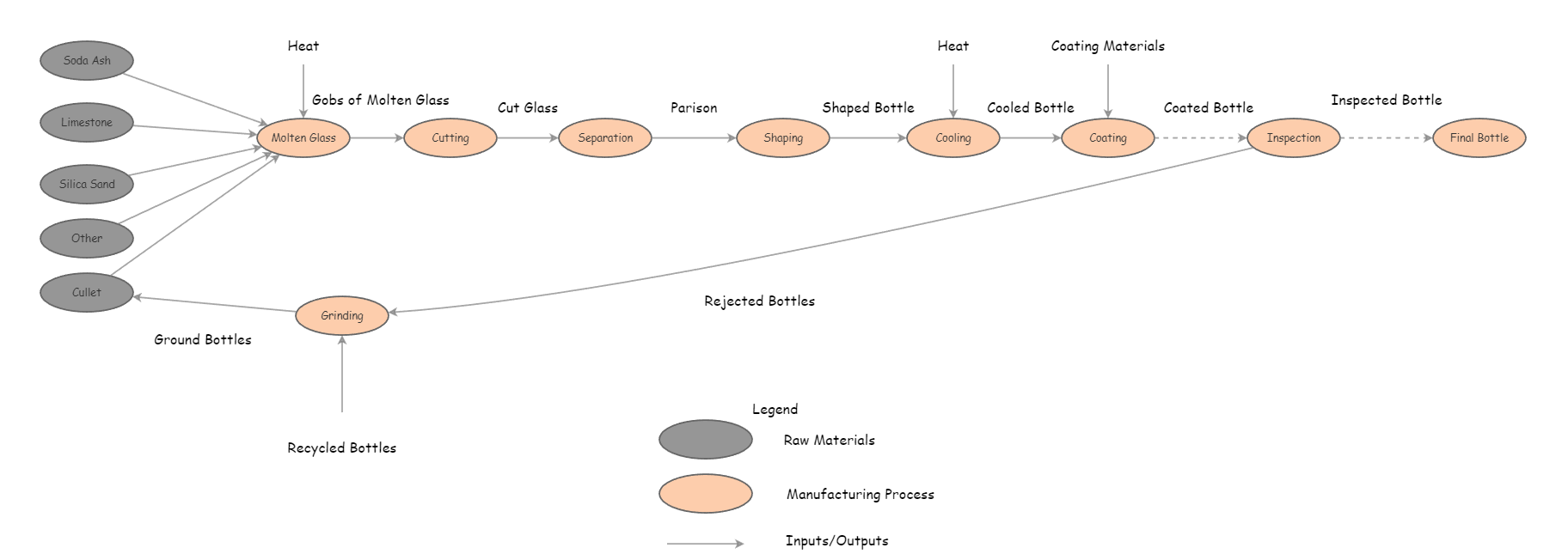

Glass Bottles Manufacturing Process Flow Diagram

General Speaking, the manufacture of glass bottle mainly in four phases:

- (1) preparation of raw material, e quartz sand, sodium sulfate or soda, chalk or limestone, dolomite and pegmatite (Vogel),

- (2) melting in a furnace,

- (3) forming by molds

- (4) finishing into packing.

The technology of glass production from the beginning to the getting of the final product consists of large investments and a thorough knowledge of the chemical formulae of the manufacture. For large companies, these are the basic requirements. It is possible to obtain this material by using of two methods: the Fourcault process and the float glass process. The technology of the Fourcault process is based on rolling of hot glass mass through specially designed rollers.